A gun vise is a specialized clamping tool designed to securely hold firearms during cleaning, maintenance, and gunsmithing work. Unlike standard bench vises that can damage finishes and apply uneven pressure, a dedicated gun vise features padded jaws, articulating mounts, and firearm-specific attachments that protect your investment while providing stable access to every angle. The Real Avid Master Gun Vise takes this concept further with 360-degree articulation, 100 ft-lb torque capacity, and a modular system of task-specific accessories that make it equally useful for AR builds, optic mounting, routine cleaning, and surprisingly, non-gun projects around the shop.

I’ve been running a Master Gun Vise on my workbench since Real Avid first released them, plus we have a second unit mounted in our event trailer where we’ve wrenched on countless competitor rifles at Tactical Games events. This isn’t a first-impressions review. It’s what I’ve learned after years of actual use.

I’ll be honest. When I unboxed this thing, I wasn’t impressed. After years of using a surplus steel vise that could probably survive a nuclear blast, the Master Gun Vise looked thin. The articulating ball and rod assembly didn’t seem particularly stout. At around $300, I was wondering if I’d made a mistake.

Those doubts lasted until my first actual project. I torqued a barrel nut to spec, repositioned the vise to work on a trigger installation, then flipped the whole thing to mount a grip on a lower receiver. By the end of that first session, I understood what Real Avid had built. The thin-looking construction is actually engineered material that’s both lighter and more than strong enough for the intended applications. The articulation that seemed gimmicky in the box became indispensable once I started using it.

Pro tip: Lubricate the ball joint when you first set it up. Mine rotated somewhat stiff out of the box, and a bit of lubricant made repositioning much smoother. Keep it maintained over time and you won’t have issues.

With a standard bench vise, you need to jerry-rig your own solutions. Wood blocks to protect finishes. Custom padding to grip weird shapes. Constant repositioning because you can only approach from one angle. The Master Gun Vise eliminates all of that.

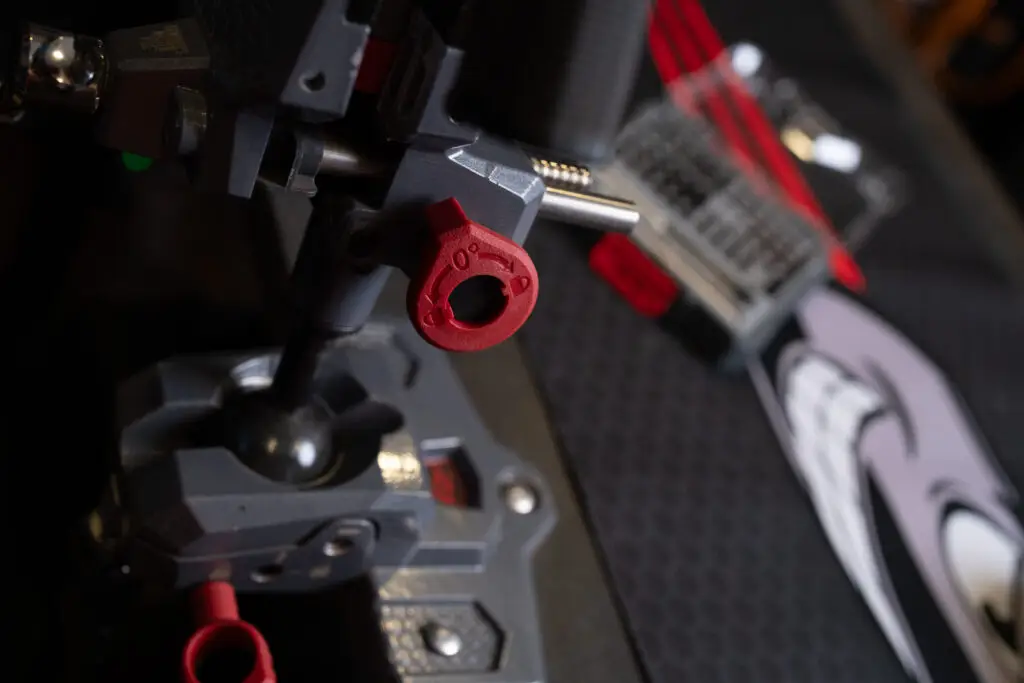

The 360-degree articulation is the headline feature, and it deserves the attention. You can position whatever you’re working on at exactly the angle you need, lock it down with the friction clamp, and get to work. Need to flip it upside down to access the underside of a lower receiver? Done. Want to angle a barrel so cleaning patches drop straight into a waste bucket? Easy.

For most tasks, the friction clamp alone provides plenty of hold. I typically pull the Torq-Lok pin out completely when I’m doing general work, only inserting it for high-torque applications like barrel nut installation or castle nut work on buffer tubes. The eight-position locking system handles up to 100 ft-lb of torque, though I’ve rarely needed more than 60-80 ft-lb even for barrel work. At those loads, I’m more worried about my workbench flexing than the vise failing.

The reversible jaw sleeves seem like a small detail, but they make a real difference. One side has grooves for positive grip on rails and cylindrical objects. The other side is padded for compression grip on delicate surfaces. The pins that secure these sleeves also anchor the Lug-Lok rod for AR upper work, so the whole system is designed to work together.

I leave mine in the original configuration to accommodate the AR15 magazine vise attachment on the jaw plates. After years of use across two vises, the sleeves aren’t even mildly beat up. The material is legit.

If you work on AR-pattern rifles, the accessory system is where this vise really earns its price.

The Lug-Lok engages directly with the barrel lugs inside the star chamber rather than clamping the outside of the receiver. This is important because traditional clamp-style blocks can actually deform or crack the upper receiver under high torque. The Lug-Lok puts all that force through the strongest structural point of the upper receiver/barrel extension, which is exactly where it should go.

I’ve used it for barrel nut installation, muzzle device swaps, and handguard changes. It’s intuitive and quick to set up. At Tactical Games events, we frequently have competitors who show up with muzzle devices that don’t meet the rules. Our trailer-mounted vise with the Lug-Lok lets us swap those devices in minutes rather than sending someone home or scrambling for tools.

I also have the AR10 version. While I’m not doing many AR10 builds, it gets regular use for muzzle device swaps and testing new configurations on my competition rifle.

The Smart-Fit block inserts into the magazine well and expands to eliminate wobble. It definitely delivers on that promise, though it sometimes takes a bit of adjusting to get it just right. The problem it can’t solve is a loose upper-to-lower receiver fit, which is a rifle issue, not a vise issue. (JP Enterprises oversized microfit pins can fix that if it’s bothering you.)

I use the Smart-Fit for any work that doesn’t require high torque. You don’t want torque transferred through the magazine well, period. Where it really shines is cleaning: lock the lower into the block, pop out the rear takedown pin so the rifle pivots on the front pin, angle the barrel toward the floor, and push cleaning patches straight down into a waste bucket. No mess, no contortion, no solvent dripping where you don’t want it.

For optic mounting where I want zero play, I’ll use the Lug-Lok even if the work itself doesn’t require torque. If the upper and lower have any looseness in their fit, that slop can throw off your mounting precision. The Lug-Lok locks directly to the upper and eliminates that variable.

The built-in leveling knob is one of those features that seems minor until you’ve used it. Combined with the Level Right Pro, scope mounting becomes a straightforward process instead of a frustrating guessing game.

My process: Mount the optic to the rifle with scope rings firm but loose enough to adjust. Verify front-to-back positioning based on your stock length and shooting position, particularly going prone to check eye relief. Get the reticle roughly aligned. Then mount the rifle in the vise, use the leveling knob to get the rifle’s base level, lock it in, attach the Level Right Pro’s projector light to the optic, level the reticle to the projected grid, and torque the scope ring screws to spec.

This matters more than most people realize. You can have perfect ballistic data dialed into your system, and it will fall apart at distance if your rifle and optic aren’t mechanically on the same plane. For anyone shooting at medium distance or beyond, a properly leveled optic is foundational. The Master Gun Vise makes achieving that level quickly repeatable rather than messing around with shooter bags or rifle saddles.

You can clean a gun with sandbags on a bench. I did it for years. But having a repeatable system matters more than you’d think.

I used to have an old MTM toolbox with rifle mounts that snapped in. Every cleaning session meant digging it out, setting it up, mounting the rifle in some awkward position where I could access the barrel without dumping cleaning solvent all over the shop. It was a pain in the ass, and because it was a pain in the ass, I cleaned my guns less often than I should have.

Now I have a dedicated space with the vise permanently mounted to the bench. Because it’s multipurpose, I don’t need to set it up or put it away. It’s always there, ready for whatever I need to do. That convenience translates directly into more consistent maintenance.

The universal clamping jaws work well for pistol optic mounting. I’ve used it for mounting red dots and, in the case of my Open Carry Optics 2311, clamping down an optic plate so I could custom-fit it with a Dremel cutting disk. The padded jaw sleeves apply enough pressure to secure the work without marring finishes.

For most other pistol work, I typically just use the benchtop directly. The vise is overkill for a detail strip or basic cleaning on a handgun. But for anything requiring precision or a stable platform, having it available makes the job easier.

Here’s something most gun vise reviews won’t tell you: This thing is incredibly useful for projects that have nothing to do with firearms.

That optic plate I mentioned trimming for my Vortex Defender XL? The vise let me mount the plate at exactly the angle I needed for a clean Dremel cut. I’ve used it to hold 3D-printed parts while drilling holes or soldering components. Minor drone repairs. Random projects with my daughter where we needed a third hand to hold something steady.

The articulating base helps with non-gun tasks the same way it helps with gunsmithing. Securely mount whatever you’re working on, rotate it to an angle where you can work on it easily, and get the job done.

Fun fact: The WorkIQ Vise is the same product marketed to a different audience. You’ll find it popular in woodworking and cycling communities because the articulating design is that versatile. If you’re someone who tinkers with more than just guns, this vise earns its bench space multiple times over.

No product is perfect, and this one has a few quirks worth knowing about.

The mounting plate design: On one of my rolling tool boxes, the friction clamp obstructs the top drawer when it’s in the locked position. Unlike a traditional vise where the handle slides up and out of the way, the Master Gun Vise’s clamp stays where it is. I’m not sure there’s a good solution to this given how the mechanism works, but it’s worth considering your bench layout before you drill mounting holes. I’m looking at Inline Fabrication plates for modularity, which might help with this issue.

Minor wobble: I notice a slight amount of play that feels like it’s between the bench and the vise rather than within the vise itself. It’s not enough to affect any work I’m doing, but it’s there. A more robust mounting solution might eliminate it entirely.

It’s not a traditional bench vise: If you need to hammer on something or apply force that would make a blacksmith nervous, this isn’t the tool. I still have a standard bench vise for tasks that require brute force or when I need to beat on something. The Master Gun Vise is built for precision work, not abuse.

I’ve had my unit since Real Avid first released them. The demo unit they provided to Action Gunner has seen even more abuse, wrenching on guns at matches in our event trailer for several competition seasons. Neither has shown any signs of wear, loosening, or degradation.

Maintenance is minimal. Keep the ball joint lubricated, keep surfaces clean and dry to avoid rust or corrosion, and it just keeps working. Nothing has broken. The jaw sleeves look essentially new despite all the work they’ve been through.

This vise makes sense if you’re regularly doing any of the following: building or maintaining AR-pattern rifles, mounting optics with any frequency, cleaning multiple firearms routinely, or working on projects beyond guns where a precision articulating vise would help.

Competitive shooters will particularly appreciate the system. Between match prep, post-match maintenance, equipment changes, and the inevitable troubleshooting, having a dedicated workspace with proper tools saves time and produces better results.

If you’re a casual plinker who cleans your guns once a year and never does any modifications, you probably don’t need a $300 vise. A basic Tipton or MTM gun vise will hold a rifle steady for cleaning, and that’s all you require.

The value proposition depends on frequency of use and variety of tasks. I make it a point to use this vise for more than just guns because it’s capable of more than just guns. If your workshop needs are narrow, the investment is harder to justify.

| Feature | Specification |

| Articulation | 360-degree multi-axis |

| Torque Capacity | Up to 100 ft-lb with Torq-Lok pin |

| Locking Positions | 8-position ball and socket |

| Jaw Sleeves | Reversible Gun-Fit (grooved/padded) |

| Leveling | Built-in precision leveling knob |

| Compatible Accessories | Lug-Lok (AR15/AR10), Smart-Fit Vise Block, Smart-Jaws family |

| MSRP | ~$299 |

The Real Avid Master Gun Vise is the first gun vise I’ve used that actually makes me want to use it. Previous setups were always compromises, things I tolerated because they were better than nothing. This one is genuinely well-designed for how people actually work on firearms.

The articulation matters. The accessory system matters. The build quality matters. And for those of us who tinker with more than just guns, the versatility matters.

At $300, it’s a significant investment compared to a basic gun vise. But if you’re doing regular gunsmithing work, building ARs, mounting optics, or any combination of the above, it pays for itself in convenience and capability. The fact that I can use it for random Dremel projects with my daughter is just a bonus.

After years of use across two units and countless projects, I’d buy it again without hesitation.

We carry some Real Avid items in our Pro Shop, you can find their products direct on Real Avid’s website (use code welcome-10 for 10% off first time purchases), or Amazon if you want to take advantage of you prime membership.

What is the best gun vise for AR-15 work?

For AR-15 specific work, look for a vise system with dedicated upper and lower receiver attachments. The Real Avid Master Gun Vise with the Lug-Lok (for uppers) and Smart-Fit Vise Block (for lowers) provides purpose-built solutions that protect your receiver while handling the torque requirements of barrel nut installation and other high-stress tasks.

Do I need a gun vise or can I use a regular bench vise?

You can use a regular bench vise with wood blocks or custom padding to protect finishes, but a dedicated gun vise offers significant advantages: padded jaws designed for firearms, articulating mounts for optimal work angles, and accessory systems for platform-specific tasks. The convenience and capability improvements make dedicated gun vises worthwhile for anyone doing regular maintenance or gunsmithing.

How much torque can the Real Avid Master Gun Vise handle?

The Master Gun Vise is rated for up to 100 ft-lb with the Torq-Lok pin engaged. In practical use, barrel nut installation typically requires 30-80 ft-lb depending on the manufacturer’s specification. The vise handles this comfortably, with the workbench often being the limiting factor rather than the vise itself.

Is the Real Avid Master Gun Vise worth the price?

At around $300, the Master Gun Vise costs significantly more than basic gun vises. The value depends on your usage frequency and variety of tasks. For competitive shooters, regular builders, or anyone doing frequent maintenance across multiple firearms, the articulation, accessory system, and build quality justify the investment. Casual shooters who clean their guns once or twice a year would be better served by a basic $50-100 gun vise.

Can the Real Avid Master Gun Vise be used for pistols?

Yes. The universal clamping jaws with Gun-Fit sleeves can secure handguns for optic mounting and other precision work. The padded jaw surface protects finishes while providing enough grip pressure to hold the pistol stable. For basic pistol cleaning and detail stripping, the vise is helpful but not essential.